HOQS

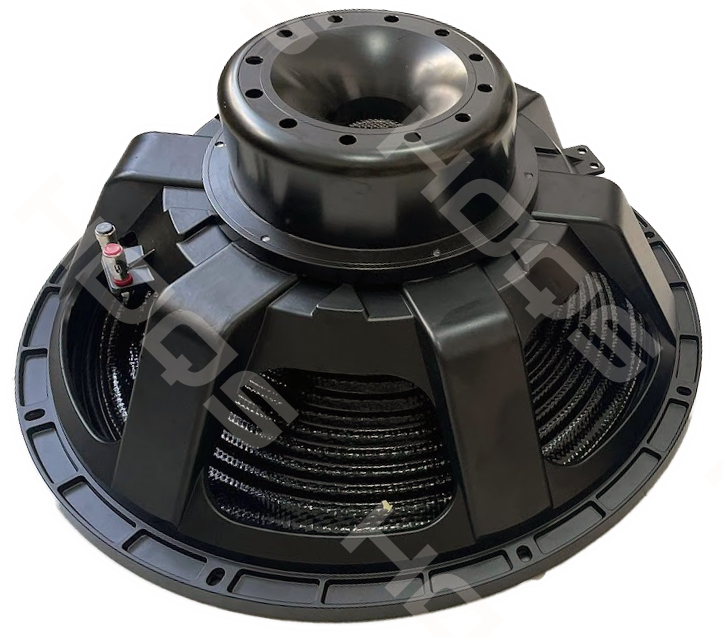

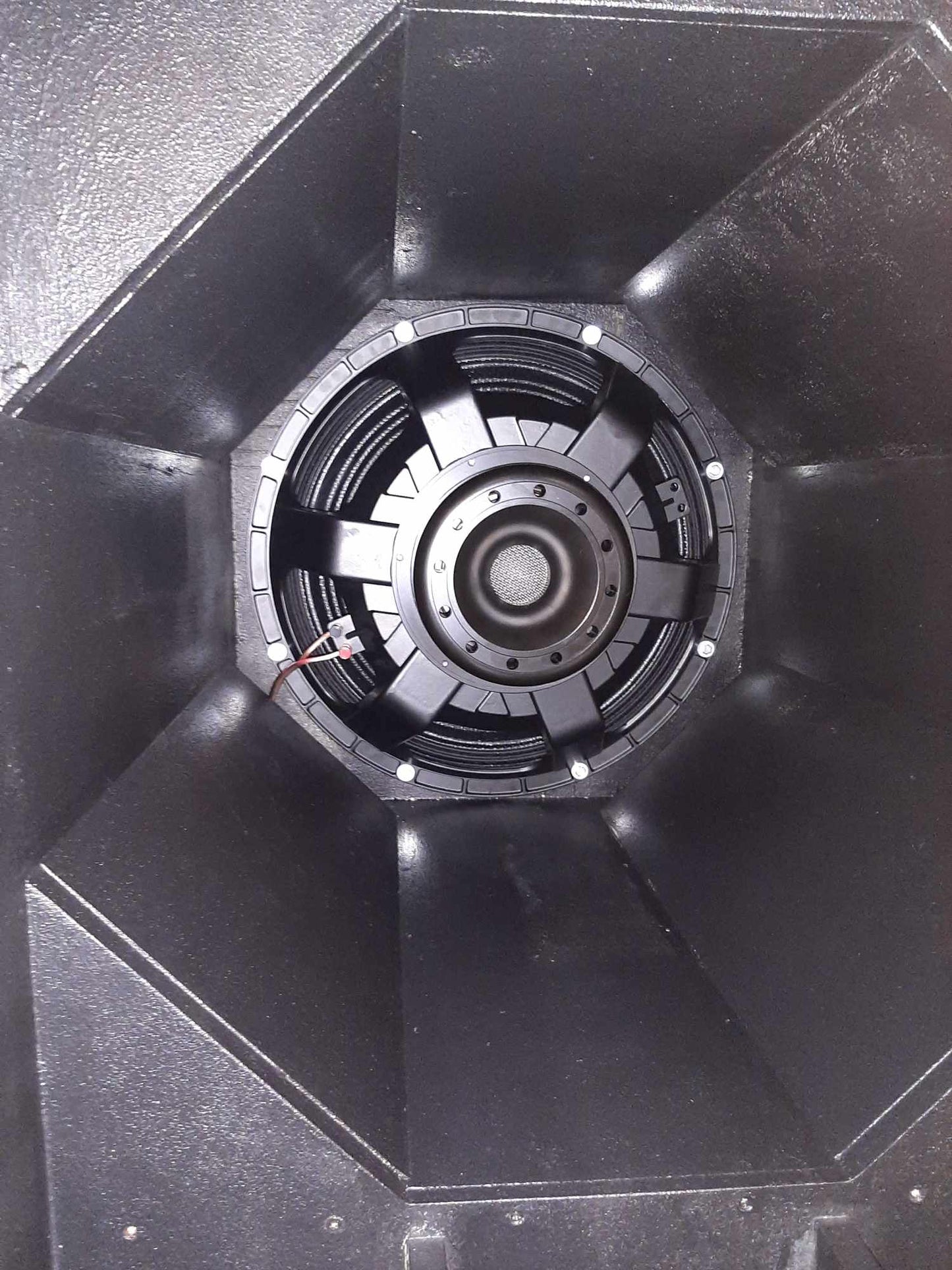

HOQS N216C 21" Neodymium LF

HOQS N216C 21" Neodymium LF

Couldn't load pickup availability

This driver's motor is designed with Finite Element Analysis modeling (FEA) and outfitted with a high grade temperature stable Neodymium magnet structure to produce an abundance of motor force.

This driver has been designed to meet the needs of HOQS Paraflex enclosures.

Paraflex enclosures are essentially Compound QW/Horn designs which place quarterwave resonators (whether flared/hornlike or not) both in front of and behind the driver(s), thereby fully utilizing the driver's front & rear wave. This alignment puts significant backpressure or loading on the driver's cone (not unlike what we can expect from other extremely efficient enclosures) which can cause distortion or even physical failure if the cone is not strong enough for the task. Therefore, as is classically known a driver well suited to this level of Horn Loading or Compound QW/Horn Loading must not only have a strong cone but also calls for a motor which is designed to remain cool enough when cone movement is well controlled (or even strictly controlled) during operation. Our F185C's motor features high grade ferrite material in the amounts required to produce force comparable to our neodymium option at less cost, and this motor force commands the load with precision & authority while the carbon fiber cone acts as our rigid resilient diaphragm for the purpose of minimum distortion and maximum output with high reliability. Last but not least this driver's suspension is designed to be sufficiently compliant for the purpose of reducing restriction to movement which is beneficial in a scenario where the driver's cone is already heavily loaded due to the very high efficiency enclosure design.

Share